18 աստիճան քայլի անկյուն M3 կապարի պտուտակային գծային քայլային շարժիչ 15 մմ Կիրառելի է բժշկական սարքերի և այլնի համար

Նկարագրություն

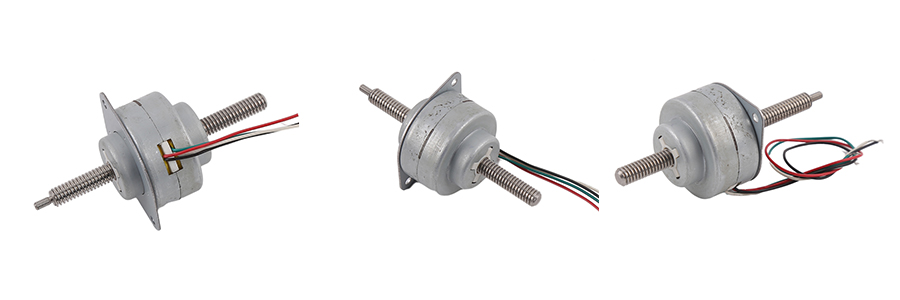

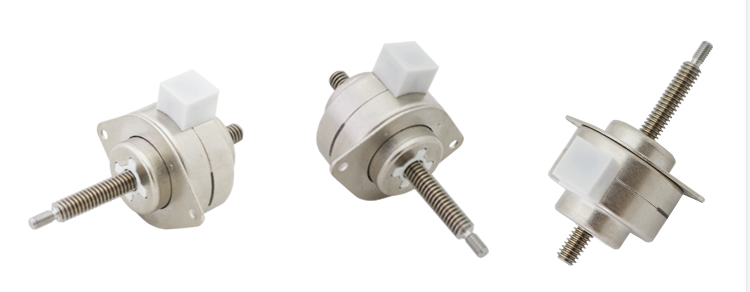

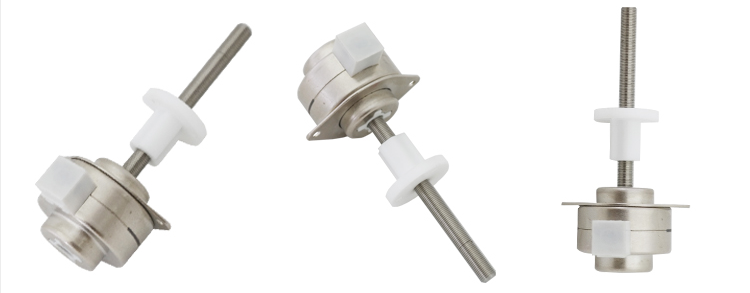

VSM36L-048S-0254-113.2-ը լիսեռի տիպի քայլող շարժիչ է ուղեցույց պտուտակով:Երբ ռոտորն աշխատում է ժամացույցի սլաքի ուղղությամբ կամ հակառակ ուղղությամբ, անհրաժեշտ է ամրացնել պտուտակաձողի վերին մասը, և ուղղորդող պտուտակն առաջ կամ հետ կշարժվի:

Շարժիչի քայլքի անկյունը 7,5 աստիճան է, իսկ կապարի հեռավորությունը՝ 1,22 մմ:Երբ քայլային շարժիչը պտտվում է մեկ քայլով, կապարը շարժվում է 0,0254 մմ, և շարժիչի պտուտակաձողի երկարությունը կարող է հարմարեցվել հաճախորդի կարիքներին համապատասխան:

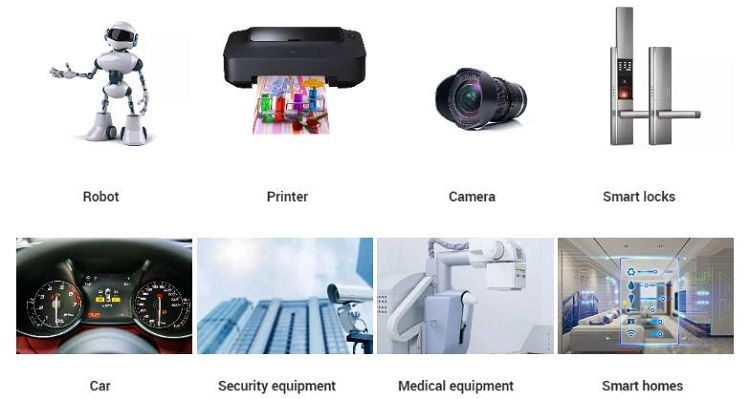

Արտադրանքը շարժիչի պտույտը վերածում է գծային շարժման՝ ներքին ռոտորի և պտուտակի հարաբերական շարժման միջոցով։Այն հիմնականում օգտագործվում է փականի կառավարման, ավտոմատ կոճակների, բժշկական սարքավորումների, տեքստիլ մեքենաների, ռոբոտների և այլ հարակից ոլորտներում:

Միևնույն ժամանակ, արտաքին լարերը կարելի է միացնել կամ դուրս գալ ելքային տուփից՝ ըստ հաճախորդի պահանջների

Մեր թիմն ունի ավելի քան 10 տարվա փորձ շարժիչի նախագծման, մշակման և արտադրության ոլորտում, այնպես որ մենք կարող ենք հասնել արտադրանքի մշակման և օժանդակ ձևավորման՝ ըստ հաճախորդների հատուկ կարիքների:

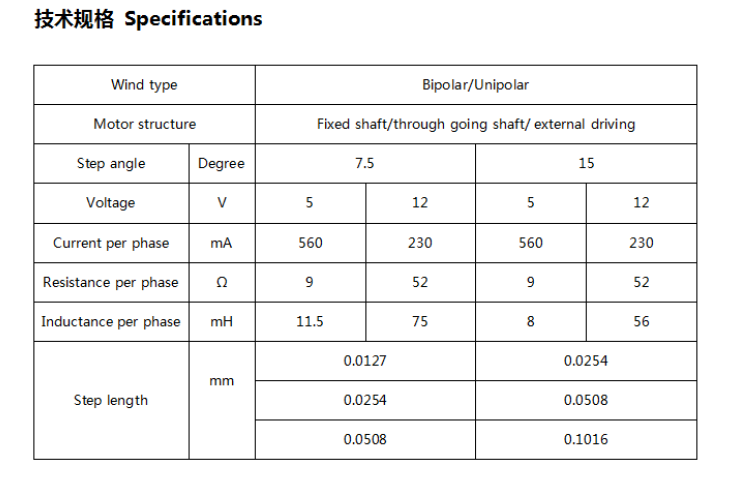

Պարամետրեր

| ԱՊՐԱՆՔԱՅԻՆ ԱՆՈՒՆ | PM36 5v Linear stepper motor |

| ՄՈԴԵԼ | VSM36L-048S-0254-113.2 |

| ՈՒԺ | 5.6 Վտ |

| ԼԱՐՄԱՆ | 5V |

| ՓՈՒԼ ԸՆԹԱՑԻԿ | 560 թmA |

| ՓԱԶԱՅԻՆ ԴԻՄԱԿԱՆՈՒԹՅՈՒՆ | 9(土10%)Օմ / 20C |

| ՓԱԶԱՅԻՆ ԻՆԴՈՒԿՏԱՆՑՈՒԹՅՈՒՆ | 11.5(±20%)mH I lkHz |

| ՔԱՅԼԻ ԱՆԿՅՈՒՆ | 7.5° |

| ՊՏՈՒՏԱԿԱՆ ԿԱՊԱՐ | 1.22 |

| ՔԱՅԼ ՃԱՄՓՈՐԴՈՒԹՅՈՒՆ | 0.0254 |

| ԳԾԱՅԻՆ ՈՒԺ | 70N/300PPS |

| ՊՏՈՒՏՈՒԿ ԵՐԿՈՒՅԹ | 113,2 մմ |

| OEM & ODM ԾԱՌԱՅՈՒԹՅՈՒՆ | Հասանելի է |

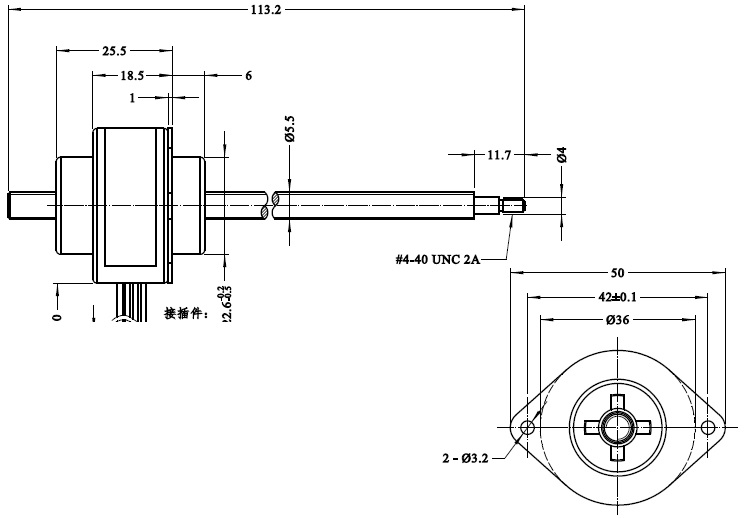

Դիզայնի գծանկար

Շարժիչի պարամետրերը և բնութագրերը

ԳԵՐԻ

Ոչ գերի

Արտաքին

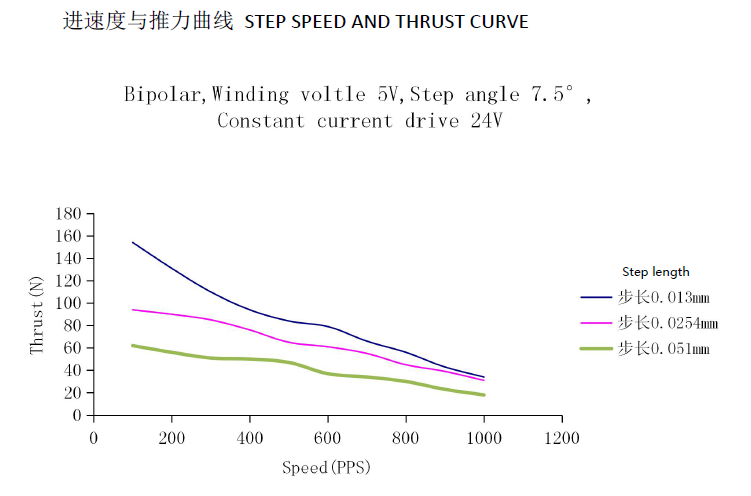

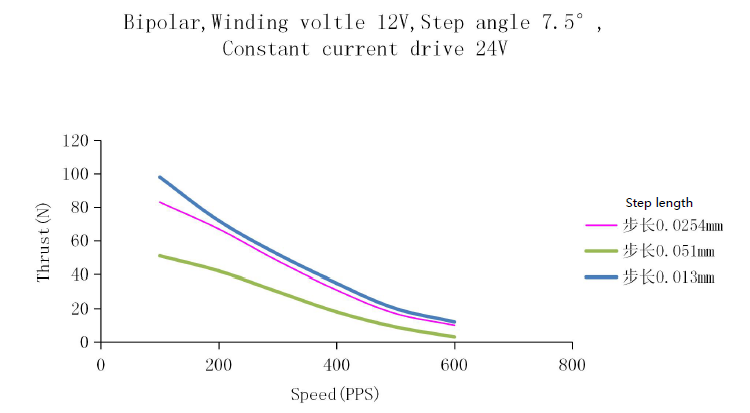

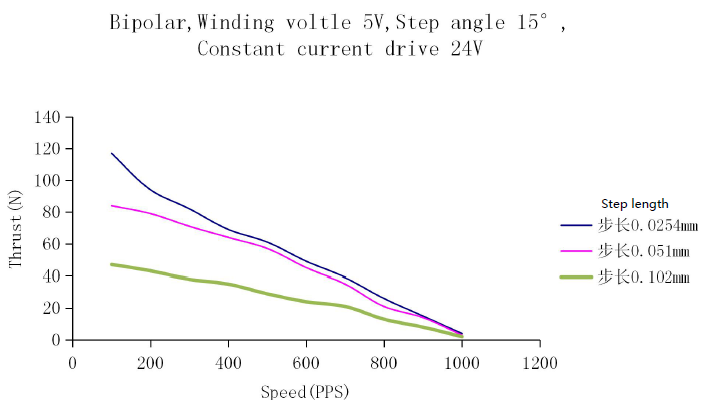

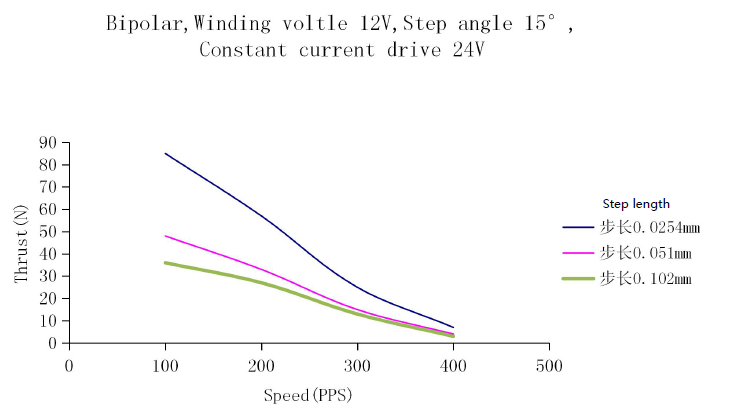

ՔԱՅԼԻ ԱՐԱԳՈՒԹՅԱՆ ԵՎ ՄԱՐՏԻ ԿՈՐ

Դիմում

Անհատականացման ծառայություն

Շարժիչը կարող է հարմարեցնել սովորական պտուտակային հարվածը,

Միակցիչները և ելքային տուփերը կարող են հարմարեցվել հաճախորդի պահանջներին համապատասխան

Պտուտակաձողը կարող է նաև հարմարեցնել ընկույզը

Առաջատար ժամանակի և փաթեթավորման մասին տեղեկատվություն

Նմուշների առաջացման ժամանակը.

Ստանդարտ շարժիչներ պահեստում. 3 օրվա ընթացքում

Ստանդարտ շարժիչներ պահեստում չկան. 15 օրվա ընթացքում

Անհատականացված ապրանքներ. Մոտ 25-30 օր (հիմք ընդունելով հարմարեցման բարդությունը)

Նոր կաղապարի կառուցման ժամկետը` ընդհանուր առմամբ մոտ 45 օր

Զանգվածային արտադրության ժամկետը` ըստ պատվերի քանակի

Փաթեթավորում:

Նմուշները փաթեթավորվում են փրփուր սպունգի մեջ՝ թղթե տուփով, առաքվում է էքսպրեսով

Զանգվածային արտադրությունը, շարժիչները փաթեթավորված են ծալքավոր ստվարաթղթե տուփերում, դրսում թափանցիկ թաղանթով:(օդային տրանսպորտով առաքում)

Ծովային առաքման դեպքում ապրանքը կփաթեթավորվի ծղոտե ներքնակներով

Առաքման մեթոդ

Նմուշների և օդային առաքման դեպքում մենք օգտագործում ենք Fedex/TNT/UPS/DHL:(5-12 օր էքսպրես ծառայության համար)

Ծովային առաքման համար մենք օգտագործում ենք մեր բեռնափոխադրման գործակալը և առաքում ենք Շանհայի նավահանգստից:(45-70 օր ծովային առաքման համար)

ՀՏՀ

Հաճախակի տրվող հարց

1. Stepper շարժիչի զարկերակային ազդանշանի դանդաղեցում:

Քայլային շարժիչի պտտման արագությունը հիմնված է մուտքային զարկերակային ազդանշանի փոփոխության վրա:Տեսականորեն, վարորդին տվեք զարկերակ, քայլային շարժիչը պտտվում է քայլի անկյունով (ենթաբաժանում ստորաբաժանման քայլի անկյան համար):Գործնականում, եթե իմպուլսային ազդանշանը շատ արագ փոխվում է, ապա հակադարձ էլեկտրական պոտենցիալի ներքին խամրող ազդեցության պատճառով քայլային շարժիչը, ռոտորի և ստատորի միջև մագնիսական արձագանքը չի հետևի էլեկտրական ազդանշանի փոփոխությանը, կհանգեցնի արգելափակման և կորստի: քայլերը.

2.Stepper շարժիչ ինչպես օգտագործել կորի էքսպոնենցիալ կառավարման արագությունը:

Էքսպոնենցիալ կորը, ծրագրային ապահովման ծրագրավորման մեջ, սկզբում հաշվարկել է համակարգչի հիշողության մեջ պահվող ժամանակի հաստատունները՝ մատնանշելով ընտրությունը:Սովորաբար, արագացման և դանդաղեցման ժամանակը քայլային շարժիչն ավարտելու համար 300 մս կամ ավելի է:Եթե դուք օգտագործում եք արագացման և դանդաղեցման չափազանց կարճ ժամանակ, ապա քայլային շարժիչների ճնշող մեծամասնության համար դժվար կլինի հասնել աստիճանական շարժիչների բարձր արագության պտույտի: